The Perseverance Rover, which safely landed on Mars on 18 February, successfully collected the first samples from the planet’s surface today. As with previous missions, various instruments will be taking measurements in situ on Mars. What is new is that samples are now being collected, which – once they have been hermetically sealed in a sample tube and temporarily stored in the sample space in the belly of the rover – will ultimately be cached at specifically designated sites on the surface of Mars. During a return mission, these samples can be collected and brought back to Earth. Back on Earth, these samples can be more accurately and sensitively analysed for their chemical composition using much more sophisticated instrumentation.

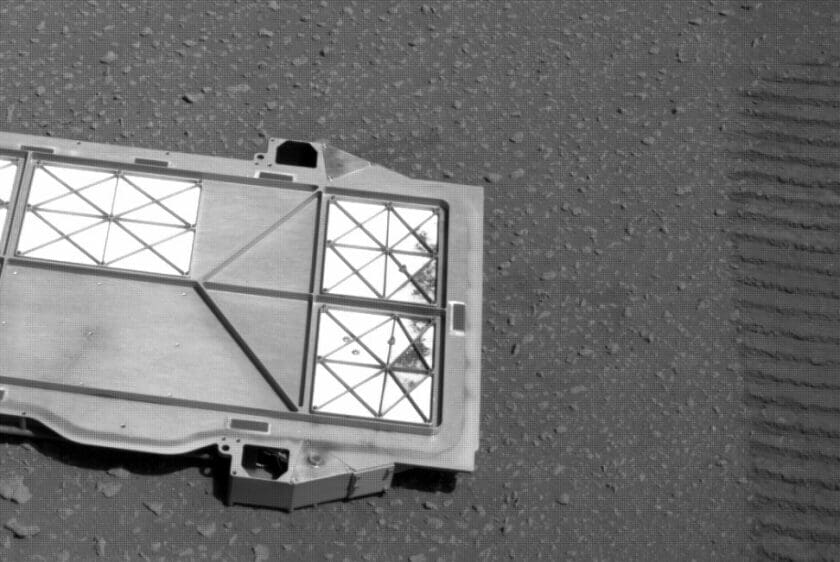

Adsorption cover

During these highly sensitive measurements, to rule out the likelihood of signals being detected from compounds not at all present in the Martian samples – for example, which have been released during the mission from materials in the rover or which may have penetrated in the Earth’s atmosphere – NASA has left nothing to chance. In addition to the necessary checks & balances for the sample tubes, any chance of foreign substances entering the enclosed space in which the sample tubes are transported, must be eliminated. To this end, engineers at the Jet Propulsion Laboratory have used thin sheets made from the high thermal stability material of TENAX, a polymer based on 2,6 diphenylphenol, which has the special property of being extremely efficient at adsorbing volatile organic compounds from the air and liquids.

Image Credit: NASA/JPL-Caltech

Niche in a niche

For the supply of these TENAXsheets, NASA called upon the services of Apeldoorn-based chemical concern, Buchem, the only company in the world manufacturing this material. Although Buchem has supplied similar such materials for missions in the past – NASA has been using TENAX for its space missions since the 1970s, when Voyager 1 began its journey to the edge of the solar system and beyond – this assignment has been particularly exciting. Jan Peter Willemsen, Senior Scientist at Buchem, explains what’s so special about the product: “For previous orders, beads of TENAX were used. These beads are sold to customers all over the world as column packing material for the adsorption of volatile substances from air or liquids. For this project however, we supplied thin sheets of approx. 10 by 20 cm in size, ensuring in the process that we were able to guarantee the same stringent specifications over the whole surface, in terms of density and adsorption of gases. Based on our experience of manufacturing disc filters, which have a diameter of 47 mm, we already had the capability to make such flat structures, but these are considerably smaller, which makes it much easier to select parts with a consistent quality. By refining the secret manufacturing process yet further, we have succeeded in meeting the required specifications for those large surfaces as well. Creating such a niche application in a market which could itself be described as niche is something quite special!”

Wait and see

The sheets were delivered to the Jet Propulsion Laboratory in 2017. “Without question, the material will have undergone all sorts of tests, but at that point it’s out of your hands as manufacturer. In fact, apart from the specifications, we knew nothing about its intended application. Only after the rover’s landing on Mars were we informed about what the TENAX sheets had actually been used for. All things said, it’s pretty exciting to see these sheets in the photos of the Mars 2020 mission”, explains Sales & Innovation manager Mathias Guggisberg enthusiastically. “As it happens, we didn’t have any serious doubts about NASA’s experiences with this form of our TENAX product, because we’d already had talks about a new project!”

Fast cancer diagnosis

New applications for TENAX have recently been discovered. Buchem’s managing director, Nico Aelmans expects to see spectacular new developments in cancer diagnostics over the next few years, in particular for stomach, bowel and lung cancer. “If you suffer from these types of cancer, you breathe out certain particles. These particles can be identified through the analysis of breathing samples, in which the relevant compounds have been adsorbed and concentrated, with the aid of TENAX. So far, it’s taken around fifteen years of research to underpin the medical evidence. Researchers have now arrived at a stage where, with the aid of artificial intelligence, the analysis results can be linked to a specific stage of a specific disease. If such a system, now being validated in clinical trials, can be used for diagnostics, this will significantly improve the treatment of these types of cancer. It’s crucial to be able to diagnosticise at the earliest possible stage of the illness: this approach can bring this moment forward sooner than is the case today.”

Jan Peter Willemsen, Senior Scientist at Buchem, together with his colleagues, succeeded in producing large TENAX-sheets with consistent quality in conformity with the stringent specifications of NASA. They are being used in the current Mars 2020 mission.

Please contact us for more information.